In the past decades, China has achieved rapid development and made remarkable achievements in the field of architecture, which has also led to the development of many upstream and downstream industries, including facade surface treatment technology and materials.

As an important part of the building materials industry, surface treatment provides a more environmentally friendly and energy-saving facade solution for green buildings and plays a key role in environmental protection. Therefore, Chinese government is stepping up efforts and the development trend of surface treatment materials and technology has become one of the hot topics of the industry.

Policy Guidance - Environmentally Friendly Coatings will Become Mainstream

In order to effectively control PM2.5, the former ministry of environmental protection formulated the Action Plan for Air Pollution Prevention, and the Ministry of Ecology and Environment has also signed The Statement of Responsibility for the Prevention and Control of Air Pollution with 31 provinces to further implement the environmental protection responsibilities of local governments.

The Law of Air Pollution Prevention and Control clearly stipulates that industrial coating enterprises shall use coatings with low volatile organic content. For furniture production, home decoration, automobile manufacturing, automobile repair, household appliances manufacturing and other industries, the government is strictly required to use environmentally friendly coatings.

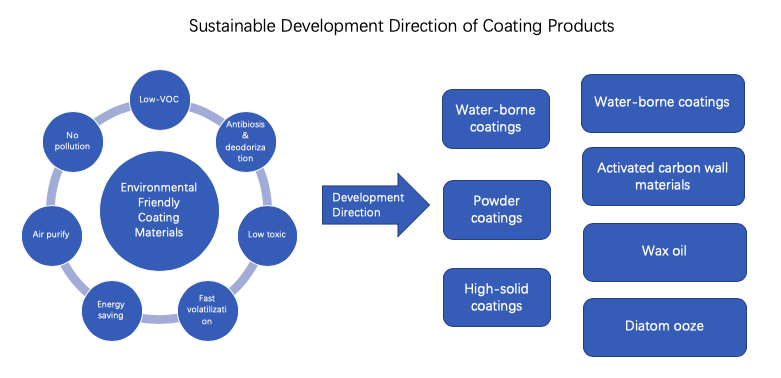

Therefore, environmental friendly coating will become a trend, and will be used in building materials more extensively.

The Trend of Environmental Protection Material is Obvious

In July 2018, the State Council issued the three-year plan to ensure greater achievement in air pollution control (Three-year Plan on Defending the Blue Sky), which imposed environmental protection tax on VOCs such as benzene and toluene from January 1, 2018. Therefore, the external cost of continuing using solvent based coatings will increase significantly.

From the aspect of policy guidance, waterborne coatings, high solid coatings, powder coatings, uv curing coatings are the main future technical research and development direction of industrial coatings. In general, coating products will develop towards three main directions including water-based, powder and high solid. Water-based materials, activated carbon wall materials and other environmental protection coating is an inevitable trend.

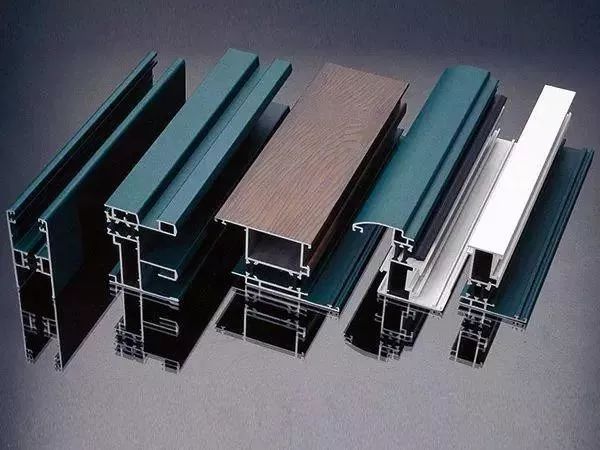

At the same time, the wood grain transfer printing technology which is more environmentally friendly than traditional wooden materials and reflect the natural feeling, is also popular in the market.

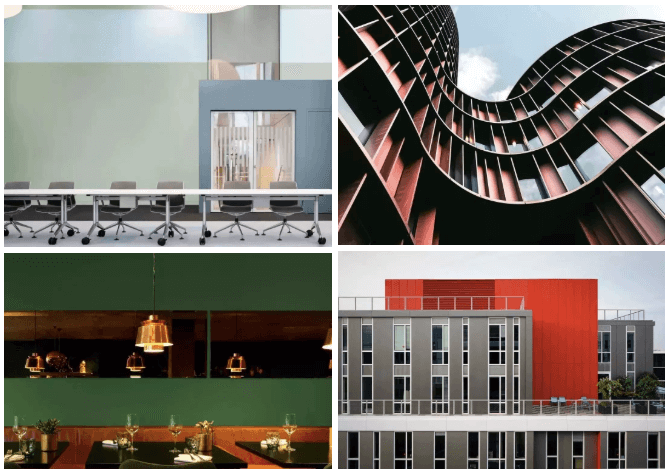

More Personalized with Better Design

AkzoNobel recently released the 2020 Color of the Year, which makes the design of buildings more aesthetic with vibrant colors. At the same time, the color trend also shows that for appearance design, the demand for bright color powder coating has increased.

More Professional with More Centralized Areas

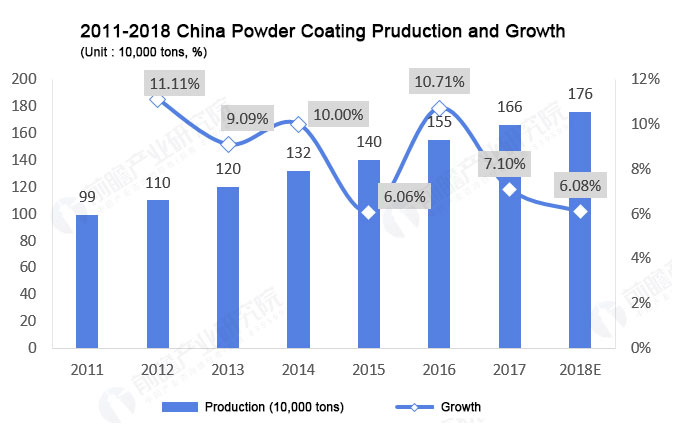

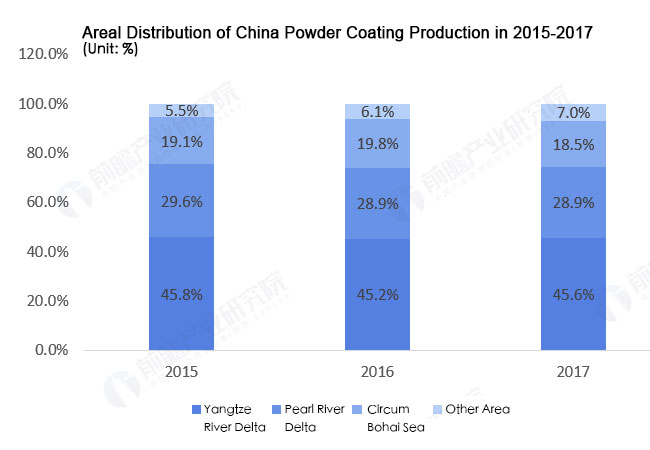

The Yangtze River Delta and the Pearl River Delta have always been the concentrated areas of powder coating enterprises in China, accounting for most of the production and sales. Due to the well-developed manufacturing industry, large economic volume, good business environment, high-quality customer base,the production of powder coatings in these two regions has steadily increased in the past two years.

The concentration of industry brings more resource advantages, and at the same time drives the benign competition among enterprises that promotes the technological progress and innovation, and eventually it’s better for the specialization of regional products.

Government Cracking Down on Inferior Products

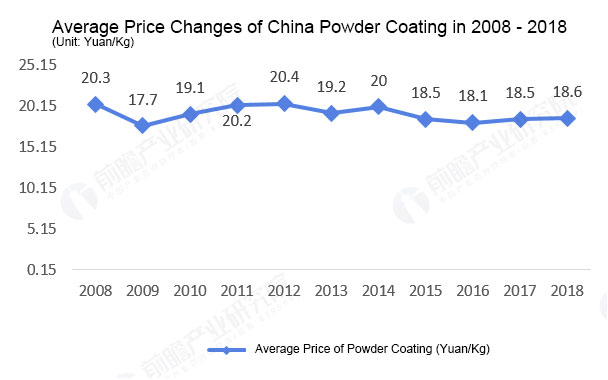

Powder coating industry is known for its low threshold and serious product homogenization. And the irrational market competition will limite the profit of powder coating enterprises.

The product price of powder coating in China fluctuates greatly. Besides the price of raw material and the fast-changing market demand, the problem of low price inferior product cannot be neglected.

Therefore, for those enterprises with stable product quality, high-end positioning and refined management, the price rise of raw materials cannot only push enterprises to innovate on products and technologies, but also drives the healthy and orderly development of the enterprise and industry.

Surface treatment materials will be showcased at the Windoor Expo China 2020, where AkzoNobel (Booth No.: 3A12), Nippon (Booth No.: 3A13), Menphis (Booth No.:4C01) will participate to discuss the most advanced surface treatment technologies and materials.